This guide will give you visual definitions for setting these values and lining everything up properly.

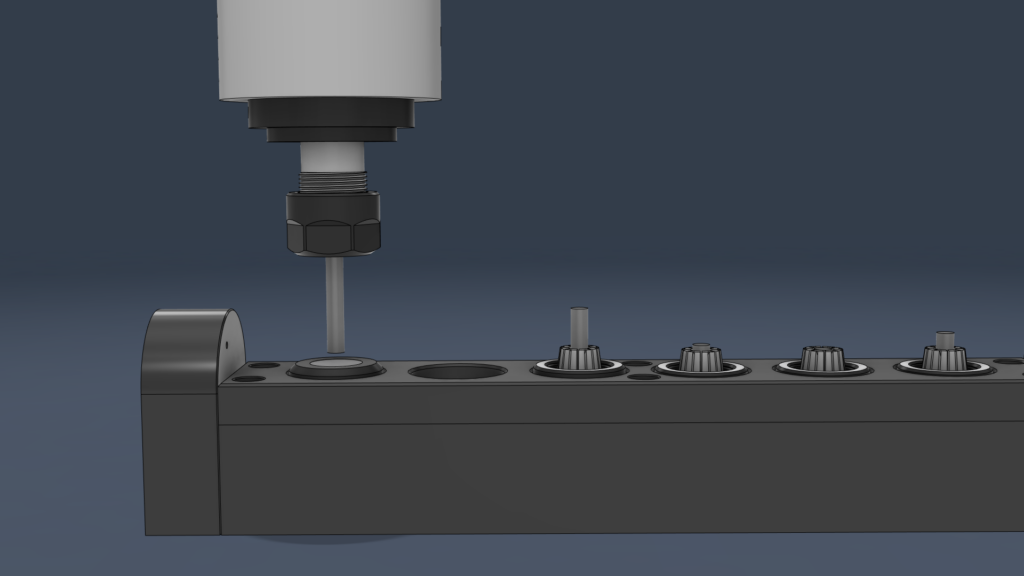

X and Y alignment

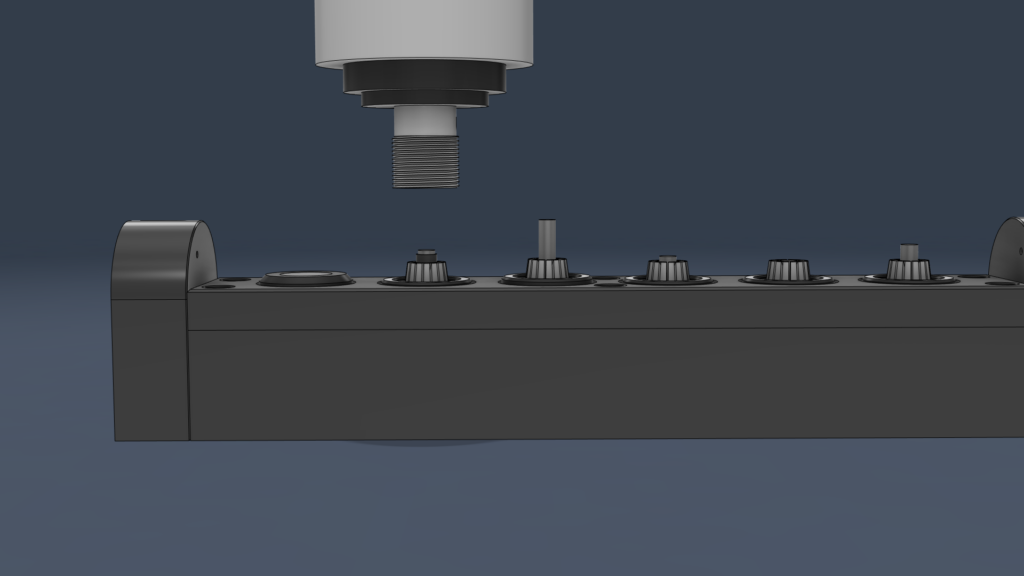

Once the magazine is mounted to the machine bed, load a tool in the spindle. position the spindle in X and Y centered on pocket 1. Visually check the position and make sure the spindle rotates freely while in the pocket but not far down enough for engagement with the socket.

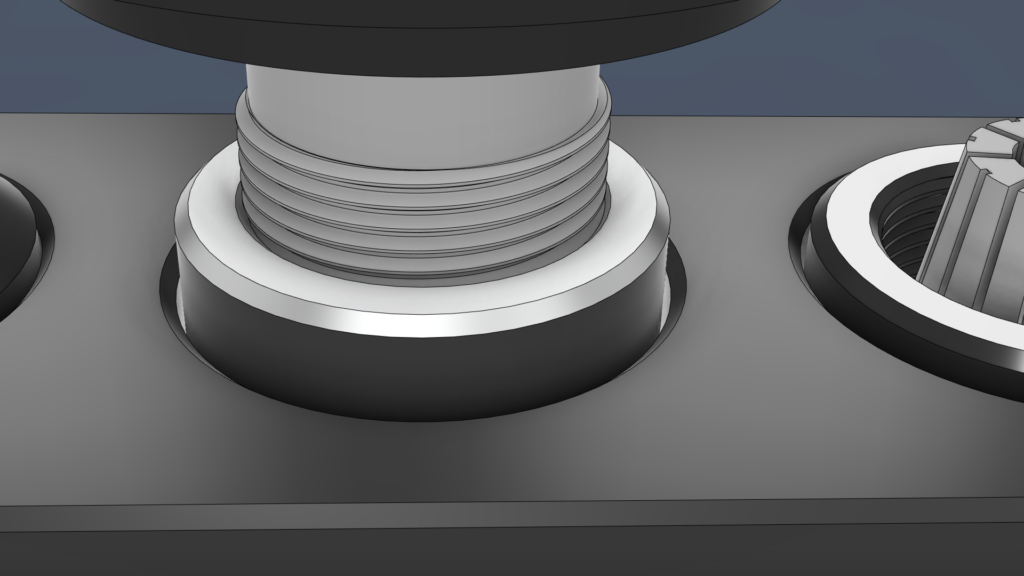

Z Engage Height

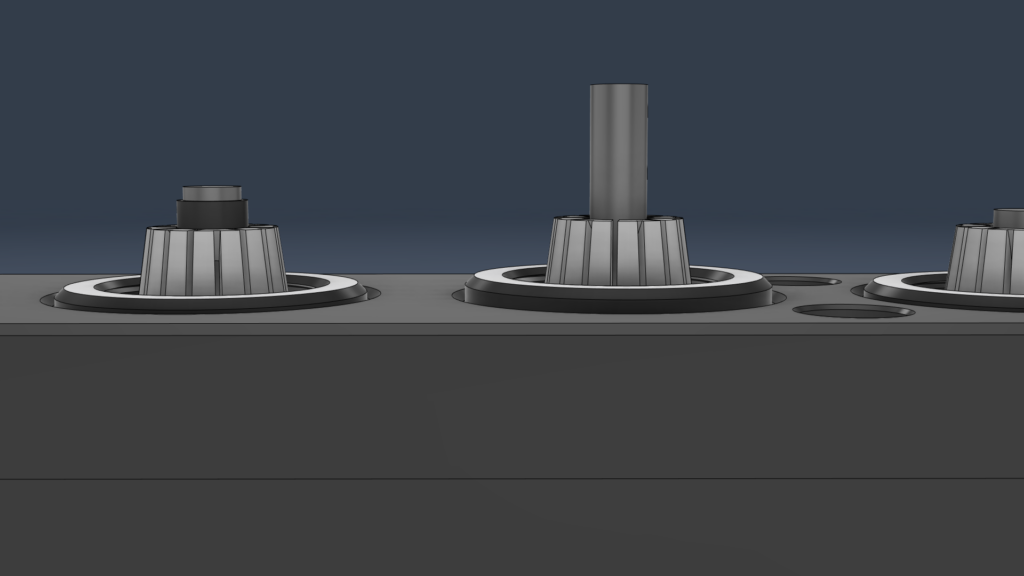

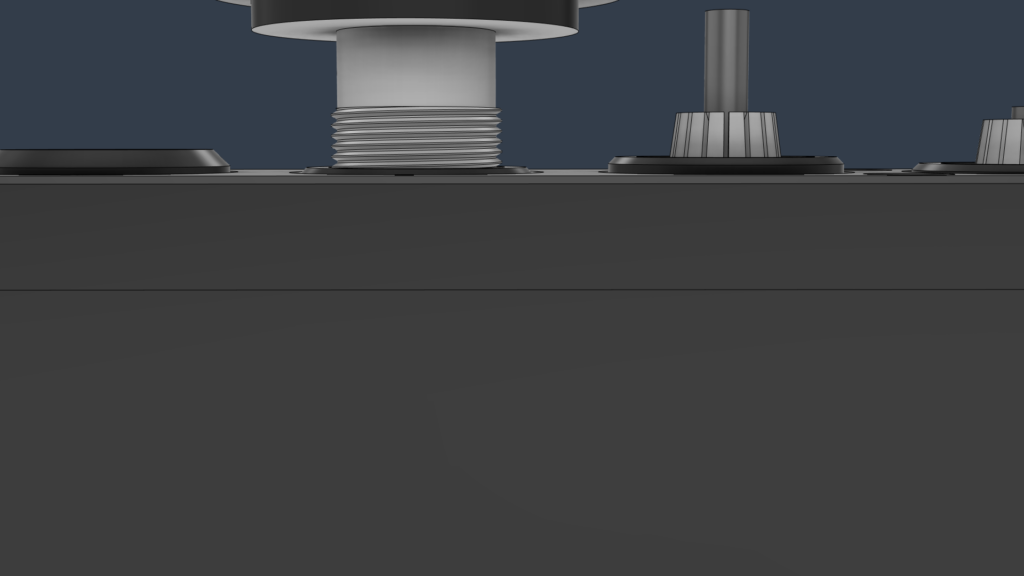

Place clamping nuts in the pockets and observe whether or not they are all at the same level. Notice that the center nut sits slightly higher than the one in pocket 1.

(Also note the wire shrink tubing keeping the tool in pocket 1 from sliding down through the spring collet. It is recommended to use collets that fit snug.)

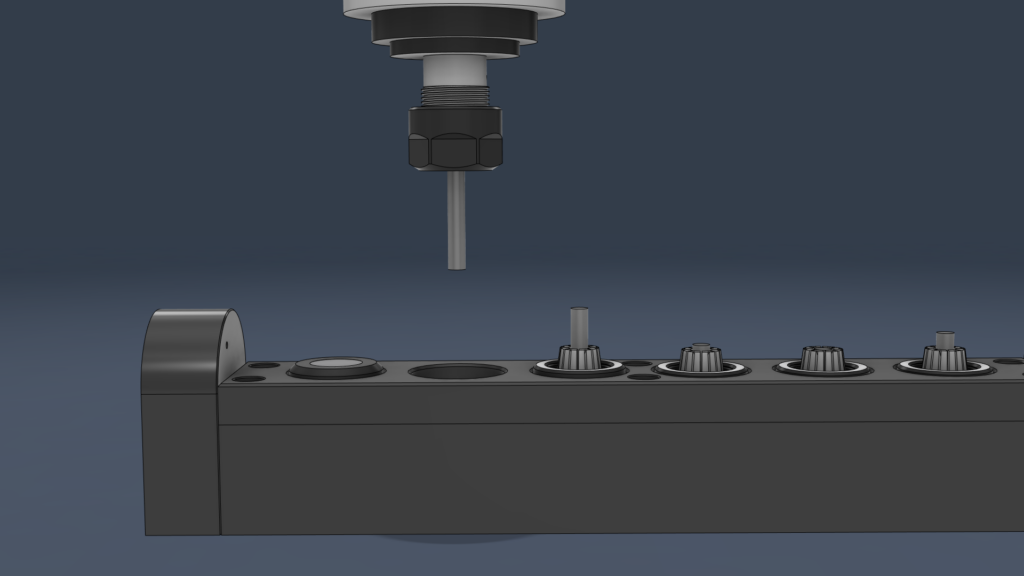

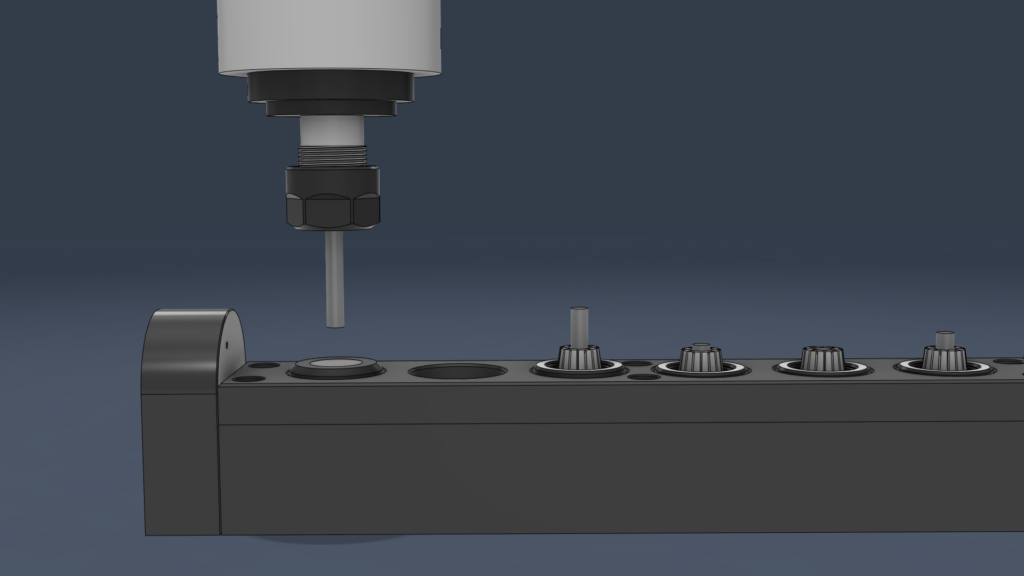

If you are using nuts from different manufacturers use the nut that sits the lowest in the pocket. Load that nut in the spindle with a collet and tool (It is vital that you have a tool, collet and clamping nut assembly in the spindle).

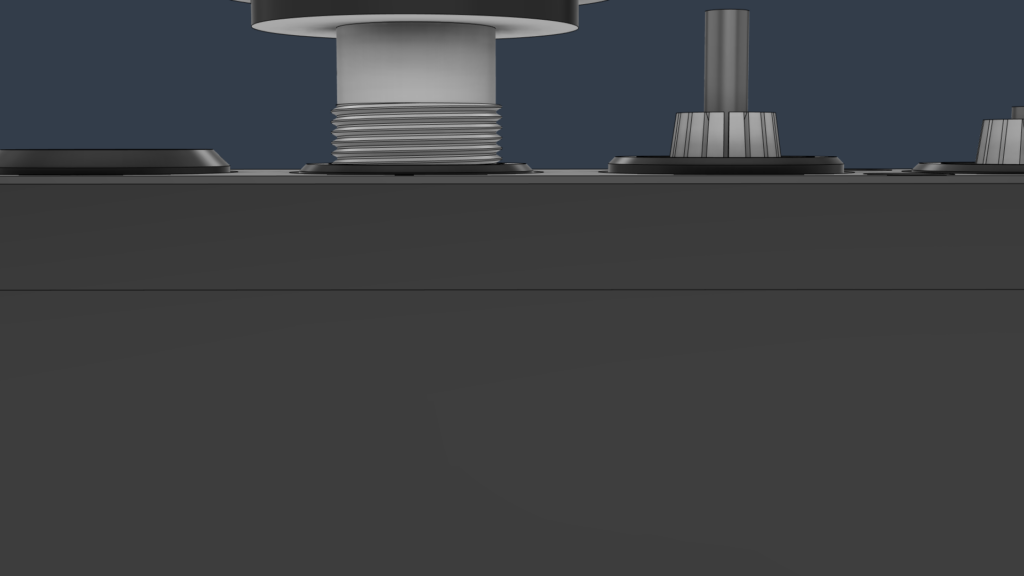

Bring the spindle down into Pocket 1 to a position just below where it would sit freely.

Now lower the spindle another 0.5mm just to make sure the nut is seated all the way down in the socket. This will be your Z engage Height.

Z Move to Load

This position is the height at which the spindle will move over the magazine after unloading a tool and moving to the next one. Be sure to clear any tools that may be sticking up out of the collet. If not using tool recognition it is best practice to set this to the safe clearance height.

Z Move to probe

This position is the height at which the spindle will move over the magazine after loading a tool and moving over the tool setter. Select a tool with the longest stick out that you will use for establishing this position. Be sure that it will clear any tools that may be sticking up out of the collet while moving over them. If not using tool recognition it is best practice to set this to the safe clearance height.

Z Seek Start

This position is the height at which the spindle will begin seeking the tool setter. Select a tool with the longest stick out that you will use for establishing this position.

Z Seek Retreat

This is the distance that the spindle will back off after the first seek touch off and begin the move down to set the tool height at a slower speed. 5mm is a good number.