Simply stated, the patent pending RapidChange ATC Magazine provides a fixed, known position for each tool location in X, Y and Z machine coordinates. The patent pending RC Socket holds the collet-nut-tool assembly against rotation. Only allowing deflection along the Z axis as the spindle plunges to load or unload the tool.

This design replaces wrenches with the RC Socket acting as the wrench by holding the clamping nut against rotation. The spindle does the work of the second wrench by spinning into the clamping nut. The rotating mass of the spindle shaft provides the force to achieve 12-15 ft. lbs. of torque to the clamping nut. The RC Socket is spring loaded to allow deflection as the nut is spun off and forcing the RC Socket down simultaneously while unloading.

RapidChange ATC Magazine Versions

The Basic version can be used as a stand alone tool change solution. It can also be upgraded with peripherals by the user.

The Premium version comes complete with a controllable dust cover and infrared fail safe protection.

Common Features of both Versions

The RapidChange ATC Magazine is machined from tough HDPE employing our unique patent pending spring loaded RC Socket design. It works with your CNC and common spindle to allow smooth and reliable tool changes out of the box. Aside from a tool setter and the ability to run your spindle in reverse for unloading tools it can be used as a stand alone unit with no inputs or outputs required.

Collet Sizes Include ER11, ER16 and ER20 for A-Type clamping nuts. ER25 and ER32 for UM-Type clamping nuts.

Macros for integrated motion control platforms as well as g code templates for writing your own macros can be downloaded from the website after purchase.

3D model .Step files are also available here if you would like to check the fit and clearances on your machine. By using the 3D model in your CAD/CAM software you can easily and precisely locate mounting holes, pocket recesses, and even mill a temporary fence or pocket to help align and fix the magazine in position. Using this method and simple math you will be able to locate pocket one easily.

Comprehensive installation Instructions and superior customer service to get you up and running quickly.

A 3D Probe Adapter for use with the supported 3D Probe allowing it to be used as a tool setter. The adapter friction fits in one one of the end pockets and a disc to replace the stylus for use as a tool setter is also included with our Premium Magazines. You also have the option to utilize any external tool touch off device you prefer.

3D Probe NOT INCLUDED.

Basic Version

The Basic Magazine is a fully functional tool change option. It comes with all the features listed above. This is for those who want to employ automatic tool change utilizing their own custom peripherals or none at all.

Premium Version

The Premium Magazine comes fully assembled and complete with the following additional features:

A MEAN WELL RD-35B 5v-24v combo power supply for the IR sensor and the stepper driver (24v is recommended for the stepper drivers).

Dust Cover Assembly

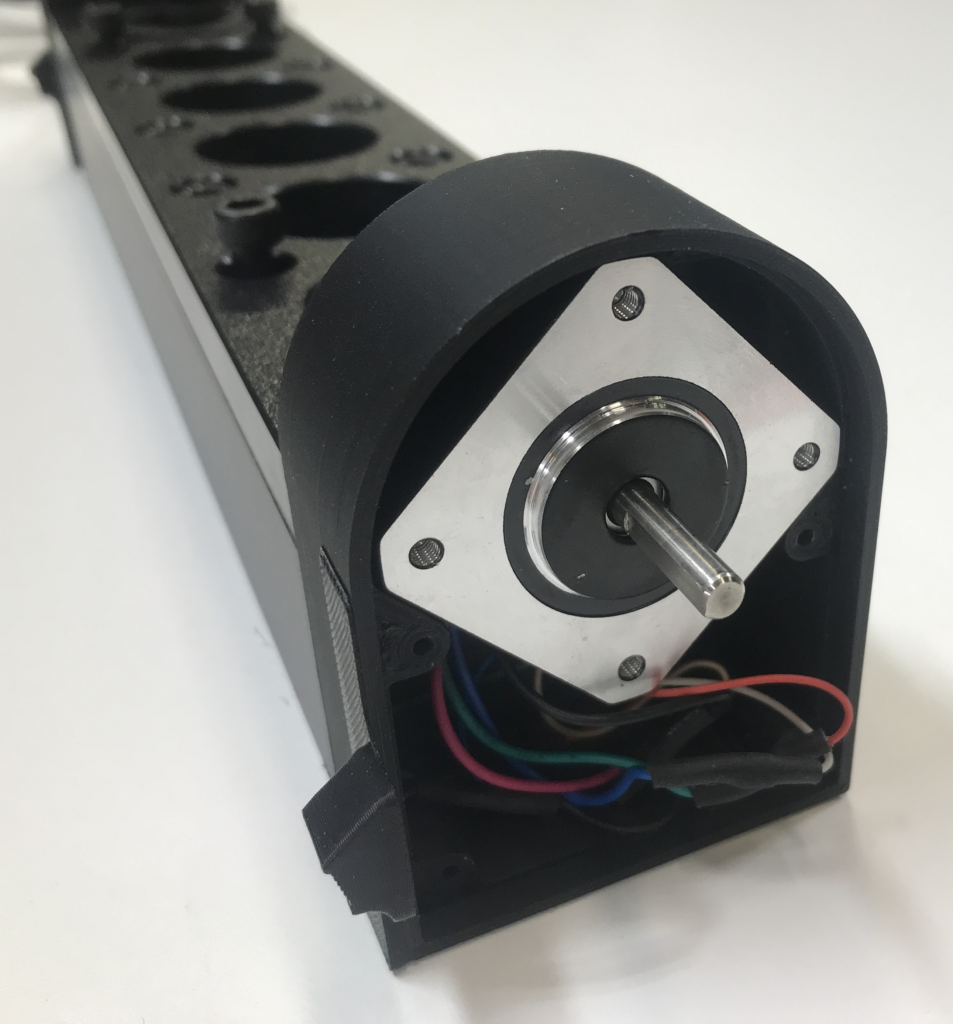

2 Nema 17 43-20 Stepper Motors to power the dust cover.

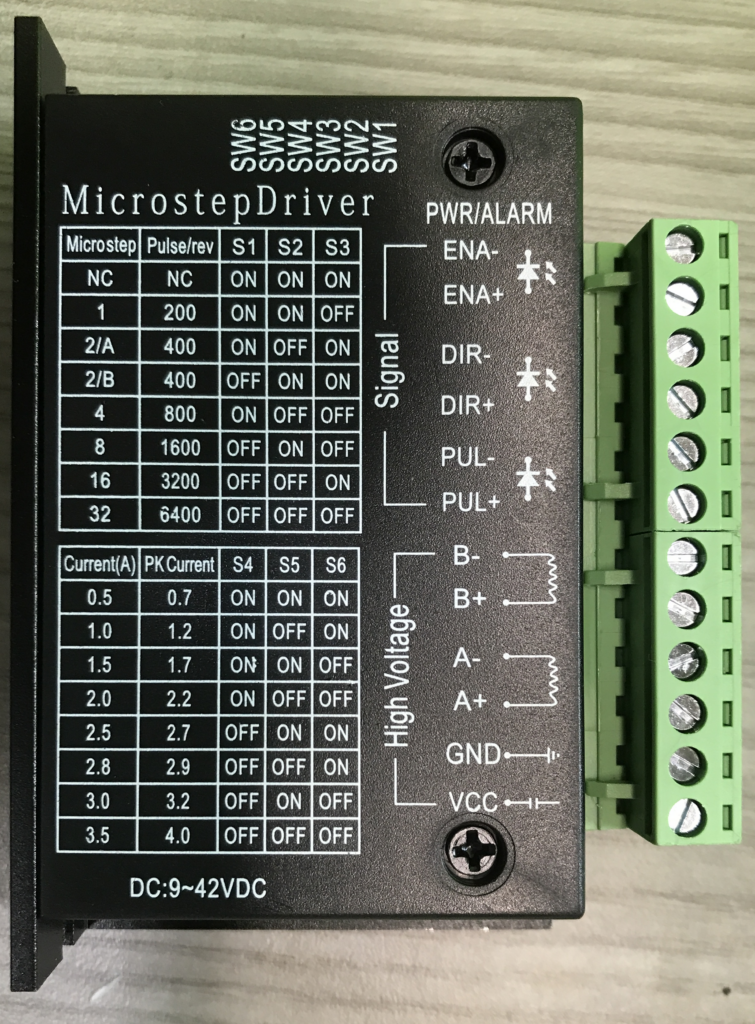

A TB6600 Stepper Driver for the 2 Nema 17 Stepper motors which drives the dust cover.

The motors may be controlled on any available axis.

OR

A 5v Interface Control Board which is included with the Premium Magazine version.

In the diagram below the signal (Purple) and common (Black) wires will open the dust cover when completing a circuit. In other words when the signal wire is pulled to ground the dust cover opens. This allows for wiring various switching devices in parallel. Allowing a wide range of choices for control.

Examples:

A rocker switch could be utilized that opens the dust cover for manual control.

An NPN proximity sensor or a N.O. mechanical limit switch could be mounted on an axis to open the dust cover when the spindle moves into position over the magazine.

An output or relay on the motion controller will activate the dust cover during the M6 call with integrated motion control software.

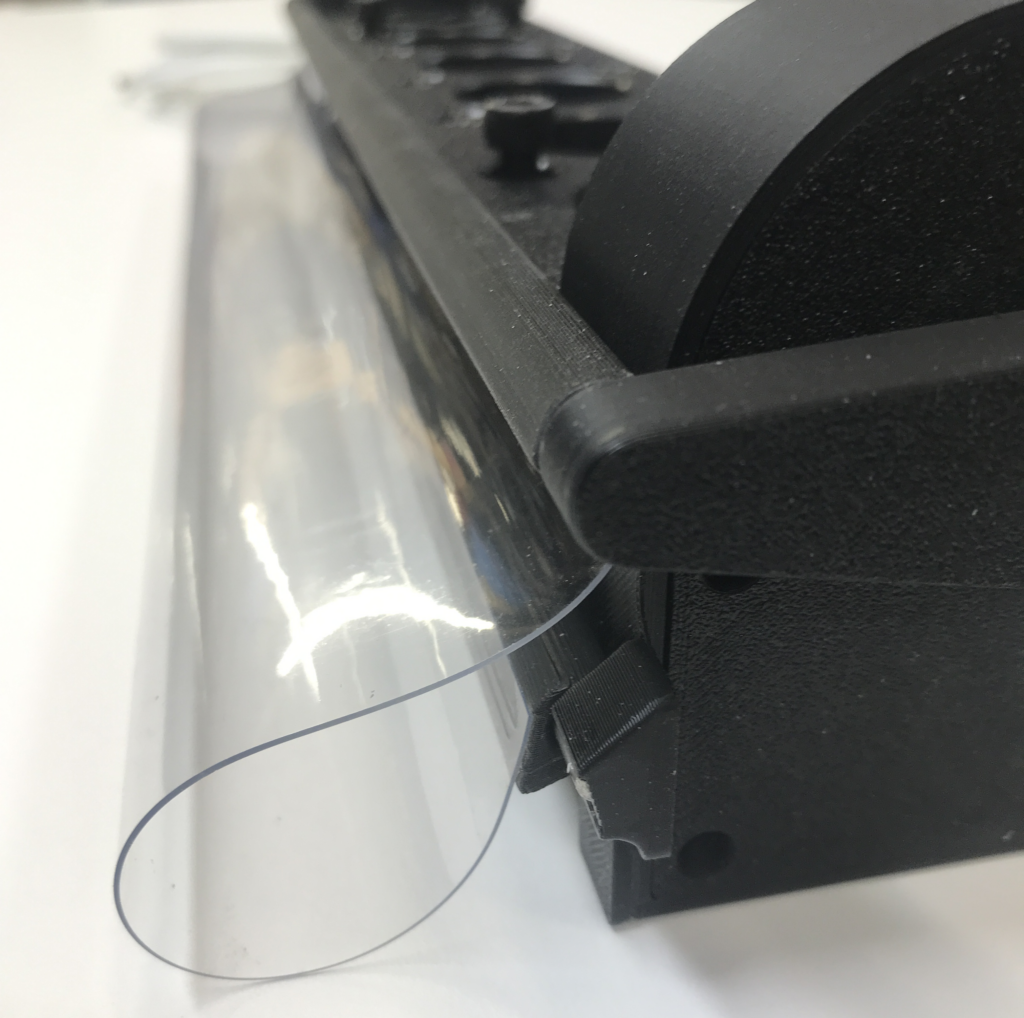

A Vinyl Dust Cover with two steel rods that pivot in the back sealing out dust and debris.

Tool Recognition Sensor

The RapidChange ATC Premium Magazine incorporates an Infrared (IR) break beam sensor for tool recognition as an added layer of protection on our integrated platforms.

The beam will detect the presence or absence of the clamping nut as a fail safe, requiring just one input pin and a 5V power source.

Poorly trammed spindles or misalignment in the X and Y axes due to events like crashes or step losses can impede the process of the tool change or cause it to fail. This could result in either no engagement, or improper threading.

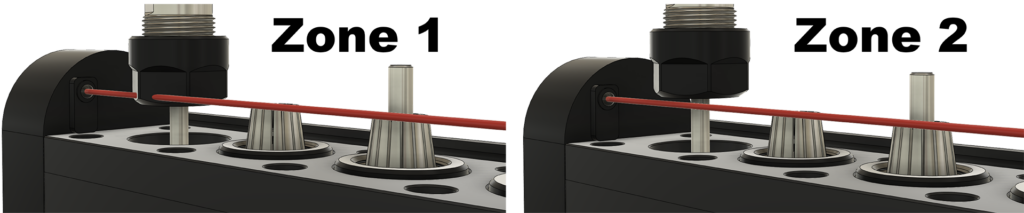

Tool recognition will detect the presence or absence of the clamping nut during a tool change. Our M6 macro checks the state of the beam while loading and unloading at Zone 1. It preforms an additional check at Zone 2 while loading. Upon failure it will pause program execution and wait for user input before resuming.

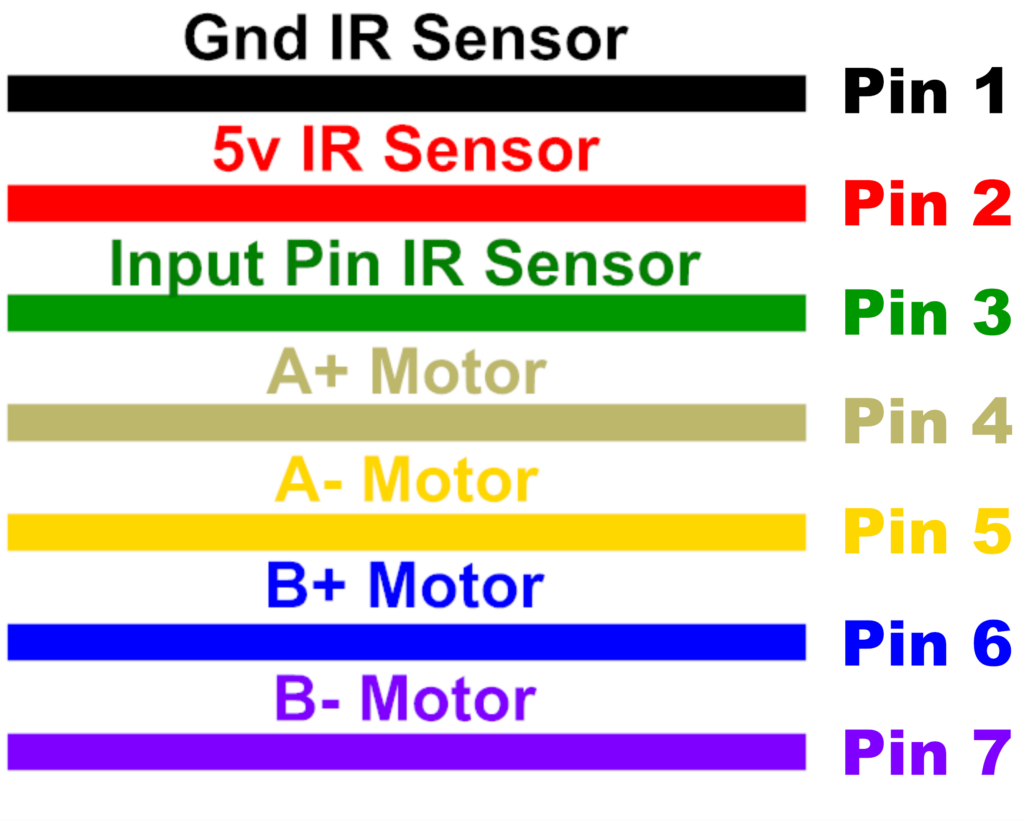

Aviation Connector

A Convenient aviation Connector with mating 6 meter cable for ease of wiring.