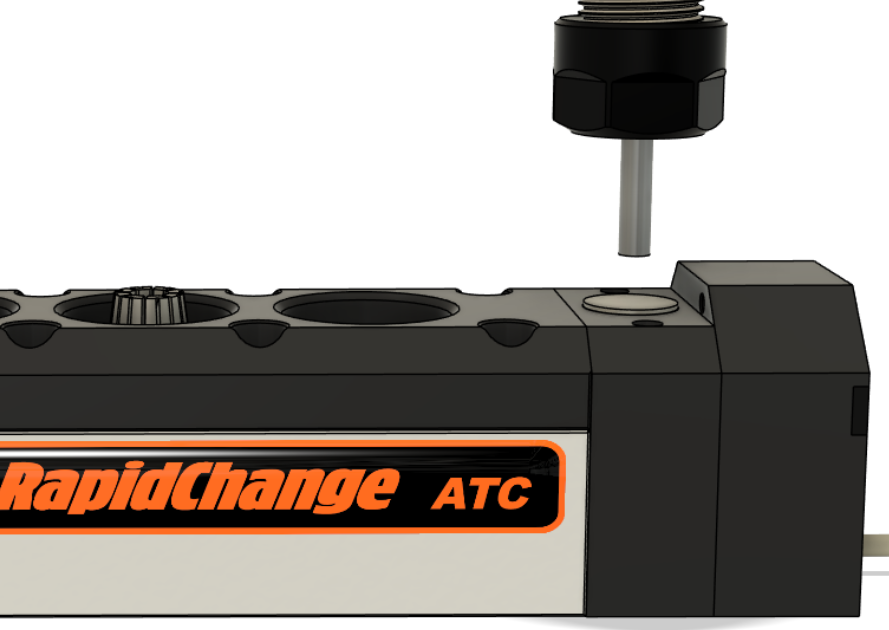

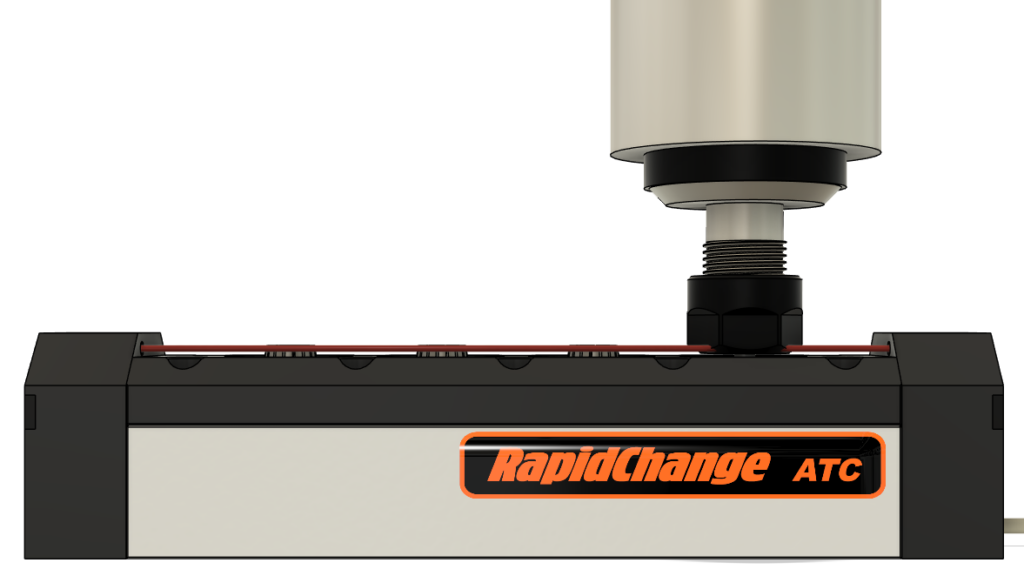

Simply stated, the patent pending RapidChange ATC Magazine provides a fixed, known position for each tool location in X, Y and Z machine coordinates. The patent pending RC Socket holds the collet-nut-tool assembly against rotation. Only allowing deflection along the Z axis as the spindle plunges to load or unload the tool.

This design replaces wrenches with the RC Socket acting as the wrench by holding the clamping nut against rotation. The spindle does the work of the second wrench by spinning into the clamping nut. The rotating mass of the spindle shaft provides the force to achieve 10-20 ft. lbs. of torque to the clamping nut based on the load rpm of the spindle. The RC Socket is spring loaded to allow deflection as the nut is spun off and forcing the RC Socket down simultaneously while unloading.

The RapidChange ATC Magazine is machined from tough HDPE employing our unique patent pending spring loaded RC Socket design. It works with your CNC and high speed spindle to allow smooth and reliable tool changes out of the box. Aside from a tool setter and the ability to run your spindle in reverse for unloading tools.

Collet Sizes Include ER11, ER16 and ER20 for A-Type clamping nuts. and ER25 for UM-Type clamping nuts.

ATC Magazine Versions #

The Basic version now comes with IR tool detection. An LED indicates when the IR sensor is triggered.

The Premium version comes complete with with IR tool detection and a low profile Polycarbonate dust cover.

Tool Setter #

Any external tool setter may be used in the tool change procedure. We are no longer incorporating the adapter for the 3D Probe due to the new low profile cover.

We have developed a tool setter which is optically triggered and very reliable. It actually tested out slightly better than the 3D Probe we had been recommending.

It also is modular so it can be easily added to our current design. Our optical tool setter will be available in our store soon. For the moment if you are interested in this add on option please contact us at info@rapidchangeatc.com

Integrated Motion Control Platforms #

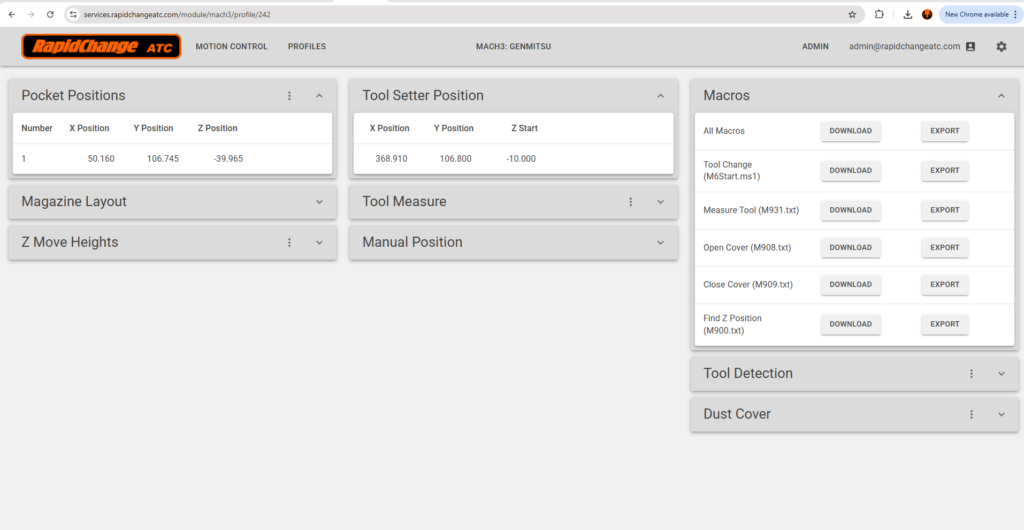

We now have a centralized configuration Web App for most of our integrations.

Currently on the Web App

Masso G3/G3 Touch

Onefinity Pro Buildbotics controller

GrblHal

Centroid Acorn CNC12

UCCNC

Mach3

Currently a Download Coming to the Web App

FluidNC

PlanetCNC

Grbl v1.1 Only works through Gsender

Mach4

LinuxCNC (there are user developed scripts available but we do not currently support it)

Macros for integrated motion control platforms as well as g code templates for writing your own macros can be downloaded from the website after purchase.

3D model .Step files are also available here if you would like to check the fit and clearances on your machine. By using the 3D model in your CAD/CAM software you can easily and precisely locate mounting holes, pocket recesses, and even mill a temporary fence or pocket to help align and fix the magazine in position. Using this method and simple math you will be able to locate pocket one easily.

Lifetime support to get you up and running quickly.

Tool Recognition Sensor #

The RapidChange ATC Magazine incorporates an Infrared (IR) break beam sensor for tool recognition as an added layer of protection on our integrated platforms.

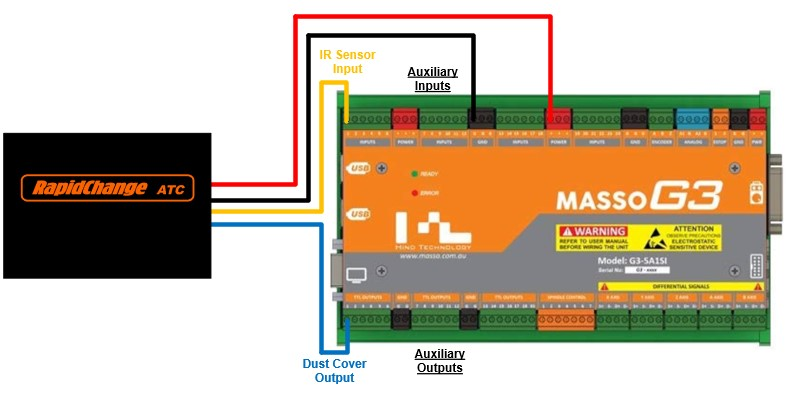

The beam will detect the presence or absence of the clamping nut as a fail safe, requiring just one input pin and a 12V-30v power source.

Poorly trammed spindles or misalignment in the X and Y axes due to events like crashes or step losses can impede the process of the tool change or cause it to fail. This could result in either no engagement, or improper threading.

Tool recognition will detect the presence or absence of the clamping nut during a tool change. Our M6 macro checks the state of the beam while loading and unloading at Zone 1. It preforms an additional check at Zone 2 while loading. Upon failure it will pause program execution and wait for user input before resuming.

Electronics #

Dust cover control has changed for the better. The Premium Linear Magazine now uses servo motors to drive the dust cover through an output on the motion controller. If an output is not available on the controller a limit switch may be used to trigger the dust cover as the spindle moves over the magazine.

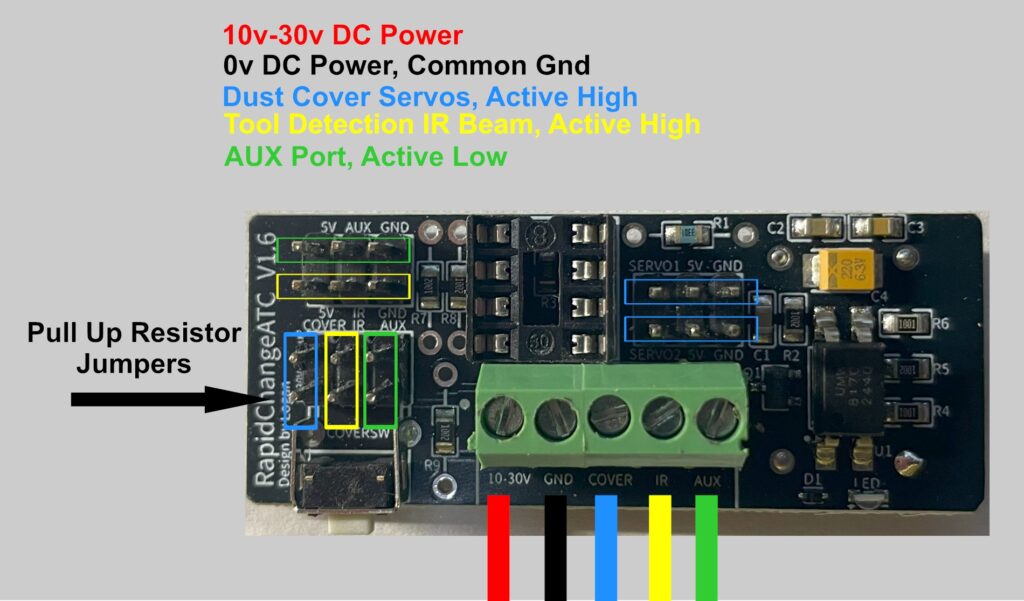

All the electronics are tucked nicely into the right end housing on the magazine. Basic Magazines come with the same V1.6 control board minus the ATTiny 85 which controls the dust cover. A 5 pin screw terminal comes prewired with strain relief. 12-36v is required and can be connected to the motion control board main power or a continuous aux power supply. (If using a separate power supply that of the motion controller the they must share a ground).

A toggle switch has been added to manually open and close the dust cover.

An indicator LED has been added which lights when the IR sensor beam is blocked.

Jumpers are available to pull signals up which some controller boards require. There is also an available AUX Port that can be used for a tool setter.

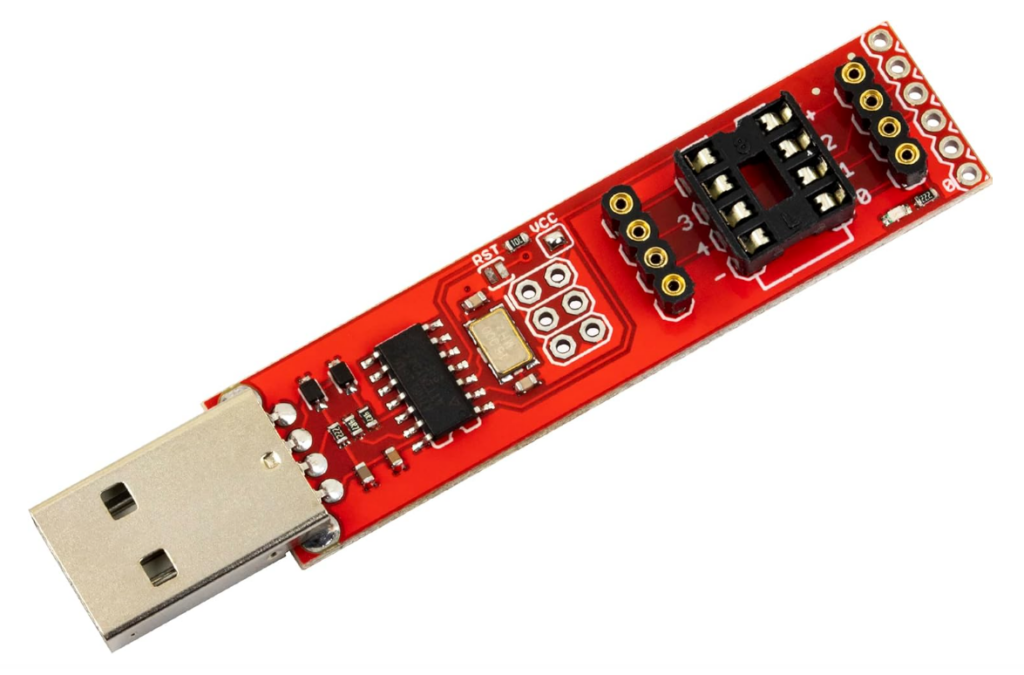

A Tiny AVR Programmer for Arduino can be used to reprogram The ATTiny 85 micro controller if need be.

https://www.amazon.com/Tiny-AVR-Programmer-for-Arduino/dp/B0BK9S6BXN

Wiring example #