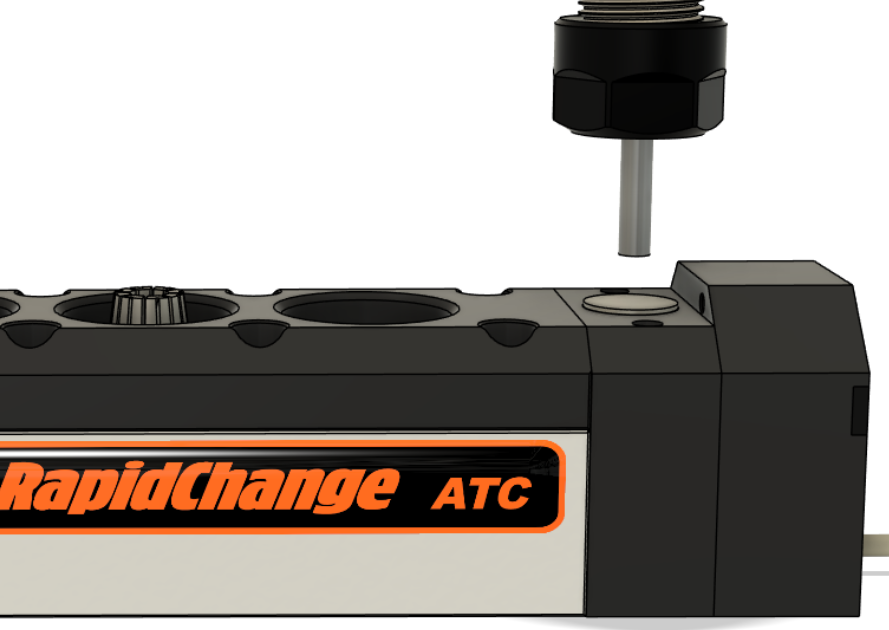

The patent pending RapidChange ATC magazine offers a hassle-free installation process, making it a valuable addition to your CNC workflow. Even if your CNC machine lacks an integrated M6 function, as long as it meets the essential spindle speed and rotation requirements, you can bid farewell to manual tool changes and embrace the simplicity of g-code macros.

Effortless Installation #

Setting up the RapidChange ATC magazine is a breeze. Use your CNC machine to precisely locate and drill the mounting holes for the provided M6-55mm socket head cap screws. A 3D mockup model with detailed mounting hole and tool pocket recess locations can be downloaded. You may use this to ensure accurate placement and check clearances.

Mount the magazine to your machine. By using the 3D model in your CAD/CAM software you can easily and precisely locate mounting holes, pocket recesses, and even mill a temporary fence to help align and fix the magazine in position. Using this method and simple math you will be able to locate pocket one easily.

Move the spindle to the first pocket, fine-tune the X and Y reference points.

Establish the Z Position. This position is easily found using the IR Sensor.

Establish movement clearances. Decide where you want the spindle to be in Z for the various moves.

Establish feeds and speeds. set the proper feed and rpm for your particular spindle and collet set up.

Establish the tool setter location. Added in the magazine with out Optical Tool Setter or any other position on the machine using any type of tool setter.

Establish seek and set feed rates for the tool touch off.

Establish Peripheral settings such as the dust cover control and tool recognition sensor with our Premium Magazine.

Begin making seamless tool changes!

Minimal Complexity, Maximum Functionality #

The beauty of the RapidChange ATC Magazine lies in its simplicity. You can achieve automatic tool changes straight out of the box without the need for compressed air, solenoids, or intricate M6 integration. While additional peripherals are available for convenience and added protection, the magazine’s core functionality is simple, and reliable..

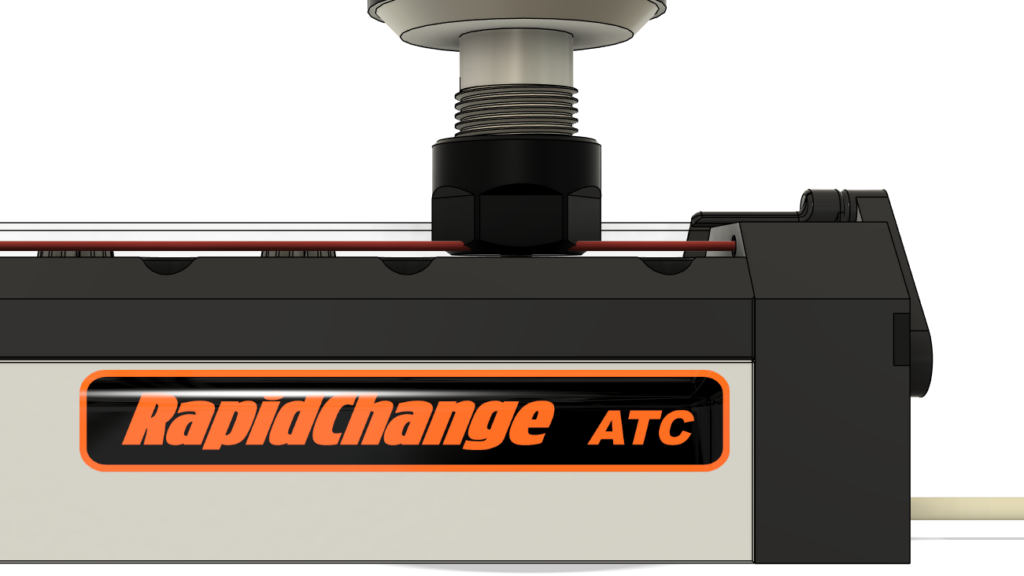

Tool Setter Addon #

Any external tool setter may be used in the tool change procedure. We are no longer incorporating the adapter for the 3D Probe due to the new low profile cover.

We have developed a tool setter which is optically triggered and very reliable. It actually tested out slightly better than the 3D Probe we had been recommending.

It also is modular so it can be easily added to our current design. Our optical tool setter will be available in our store soon. For the moment if you are interested in this add on option please contact us at info@raspidchangeatc.com

Reliable Tool Recognition #

All RapidChange ATC Magazines comes with an infrared tool detection sensor for added security during tool changes, requiring an input on the motion controller or breakout board. This feature ensures reliable tool changes.

Flexible Dust Cover Control #

The RapidChange ATC Premium Magazine comes with servo control for the dust cover, providing a comprehensive solution to the problem of dust and debris management in CNC environments. It can be controlled several ways for maximum flexibility.

Power Supply #

The system requires a 12v-30v and can be connected to the same power supply as the controller.