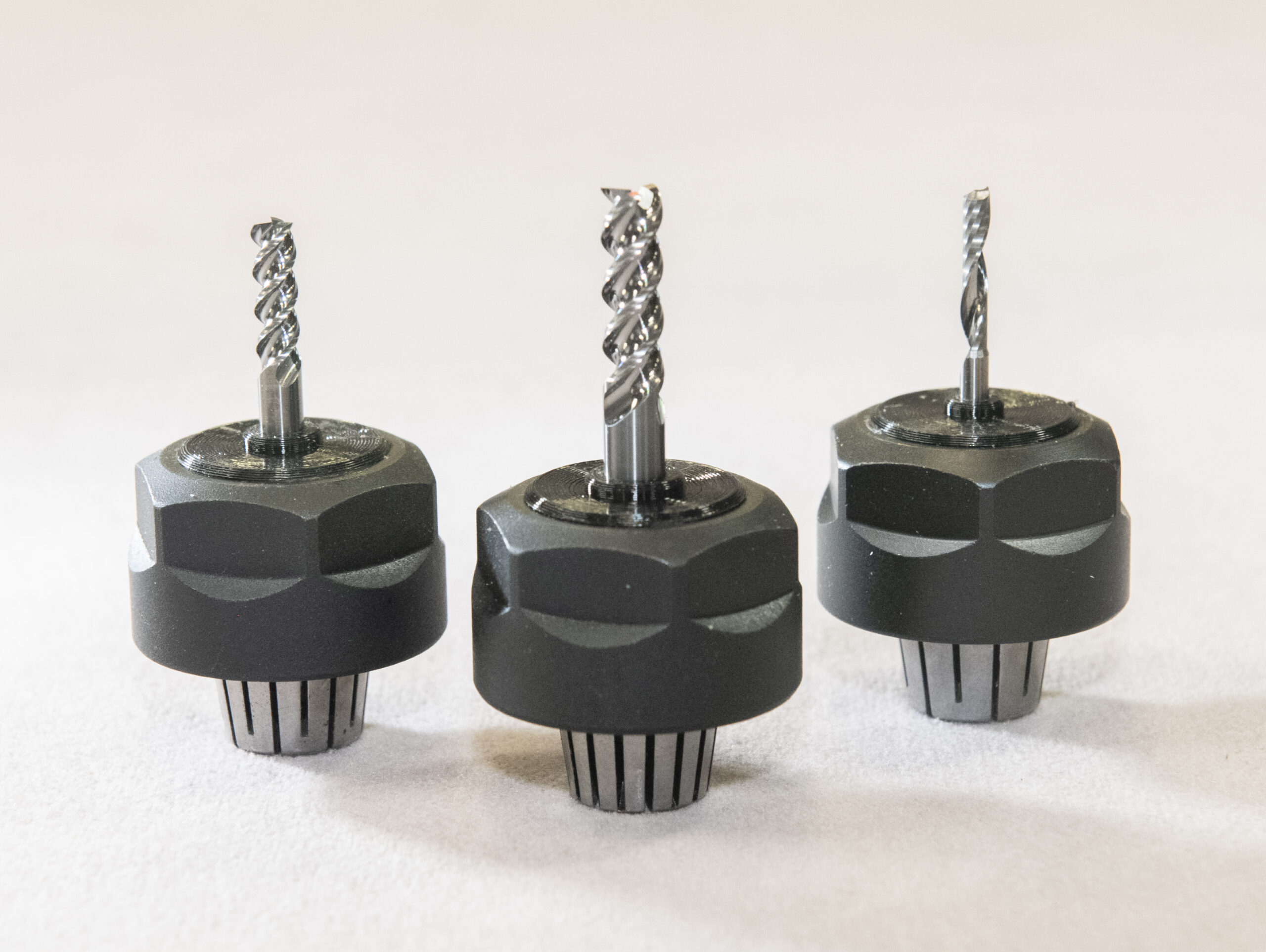

Collet Shields

Category Accessories

Description

Our Collet Shields are designed to keep cutters from slipping out of the collet while at rest in the Magazine or Turret and limit cutters from creeping up in the collet over multiple tool changes.

Collet Shields are printed with TPU and engineered to solve common problems faced by CNC operators:

- Prevent Slipping at Rest: Keep cutters from falling out of your collet while in the tool magazine or turret.

- Significantly Reduce Creep: Stop cutters from moving significantly deeper into (or out of) the collet over multiple tool changes.

- Protect Your Collets: The exposed face of your collet is sealed, keeping out dust and debris that can degrade performance and shorten collet life.

Our extensive testing in our own machining has produced great results for us. Your results may vary.

| Benefit | Without Collet Shield | With Collet Shield |

|---|---|---|

| Chamfer Bit Creep | Adjustment every 10 tool changes | Lasts over 200 tool changes before showing comparable creep. |

| General Cutter Stability | Varies greatly | Less than 0.1 mm creep over 50 tool changes for some cutters |

Collet Shield variety pack sizes 1/8″-3/16″-1/4″-3/8″-1/2″

Simple Setup & Removal

Attaching your Collet Shield is straightforward:

- Place the Collet Shield on the cutter.

- Run a bead of CA glue around the outside of the Collet SH.

- Load the collet/nut assembly on the spindle by hand. This ensures the cutter is perfectly centered within the clamping nut.

- Firmly press the Collet Shield against the clamping nut.

- (Optional) Spray some CA glue activator for faster curing.

Removal:

- Remove the cutter from the collet/nut assembly.

- Use a putty knife or utility knife to pry the Collet Shield from the clamping nut.

Multiple Use:

Once installed, you can replace the cutter with another one of the same diameter without needing to remove the Collet Shield.

!! COLLET NUTS & COLLETS ARE NOT INCLUDED !!

Be the first to review “Collet Shields” Cancel reply

Reviews

There are no reviews yet.