Description

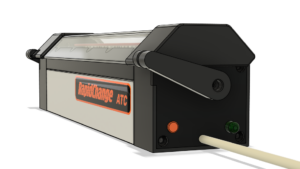

ER20 6 Pocket Premium

Patent Pending RapidChange ATC Magazines allow for the use of cutting tools with a maximum diameter of 30mm for ER20 collets and is designed for A Type clamping nuts.

The ER20 6 Premium Magazine allows for safe unattended use by employing our innovative Tool Detection. It also includes a clear polycarbonate cover that provides a good seal against dust and debris.

RapidChange ATC Magazines are machined from tough HDPE employing our unique patent pending spring loaded socket design. This design utilizes the CNC’s motion control and a VFD spindle to perform smooth and reliable tool changes. Along with a tool setter automatic tool changes are possible with minimal installation.

Macros for integrated motion control platforms are templated in our Web App. Just enter the variables for your machine and generate the macro files,

Dimensions for all magazine variations can be found HERE.

If you would like to check the fit on your machine we have mock up 3D models in .STEP format on our Discord Server for download.

Comprehensive installation Instructions to get you up and running quickly.

A Tool Setter is required and any external tool setter may be used in the tool change procedure. We are no longer incorporating the adapter for the 3D Probe due to the new low profile cover.

We have developed a tool setter which is optically triggered and very reliable. It actually tested out slightly better than the 3D Probe we had been recommending.

It also is modular so it can be easily added to our current design. Our optical tool setter is now available.

Dust Cover Control has changed for the better. The Premium Linear Magazine now uses servo motors to drive the dust cover through an output on the motion controller. If an output is not available on the controller a limit switch may be used to trigger the dust cover as the spindle moves over the magazine.

All the electronics are tucked nicely into the right end housing on the magazine.

12-30v is required and can be wired to the motion control board main power or a continuous aux power supply.

Red Power 12-30v input.

Black Gnd. (If using a separate power supply that of the motion controller the they must share a common ground).

Blue Dust Cover signal wire is connected to an output on the motion controller active low.

Yellow IR signal wire is connected to an input on the motion controller active high.

Logan Smith (verified owner) –

I have had the pre release version of this magazine for about 2 months now and my only gripes are solved with this version with the dust cover and height sensor. I use Mach 3 on my home built router; the amount of time this saves is crazy. It took a few weeks to get used to the cam and workflow changes, but once you are past that it is second nature. I use 1mm to 13mm endmills in mainly aluminum and a bit of steel. I never had it slip, and I use down cutting bits. The initial set up was about 1 hour, with the documentation it should be less now. With my vfd tourqe curve it takes 18 seconds to change an endmill. I highly recommend this for anyone who wants to make some money with their machine.

I also am happy to use a product that is made by people who are passionate about it and take pride in their work, down to the last detail.

Guillaume Ferland (verified owner) –

I use the rapid change atc on my shariff dmc2 cnc 14×10 inch table. I mostly machine 70 and 60 series aluminum sometimes 4140 steel. I have a Masso g3 controller. I was worried it would take too much space on my machine table but was really surprised how compact and simple it is to setup, no air needed, that’s a big plus for me. The cover is really good to keep chips and coolant out. The workflow with the toolsetter works really well. I used to design my parts with the intention to fabricate it with the fewest tools count. But now I got my deburring tool, engraving tool and facing tool always loaded, it makes better looking parts for less work.

Thanks you so much!

jean-philippe leduc (verified owner) –

ome word amazing! work perfectly, when basic setting are set its the perfect addon to any cnc fast easy and well think. support its amazing and fast this should been on the market for a long time its what all we need nothing to change to the hardware of the cnc just bolt it set position and goooo tanck to rapidchange crew !!