Description

ER16 4 Pocket Premium

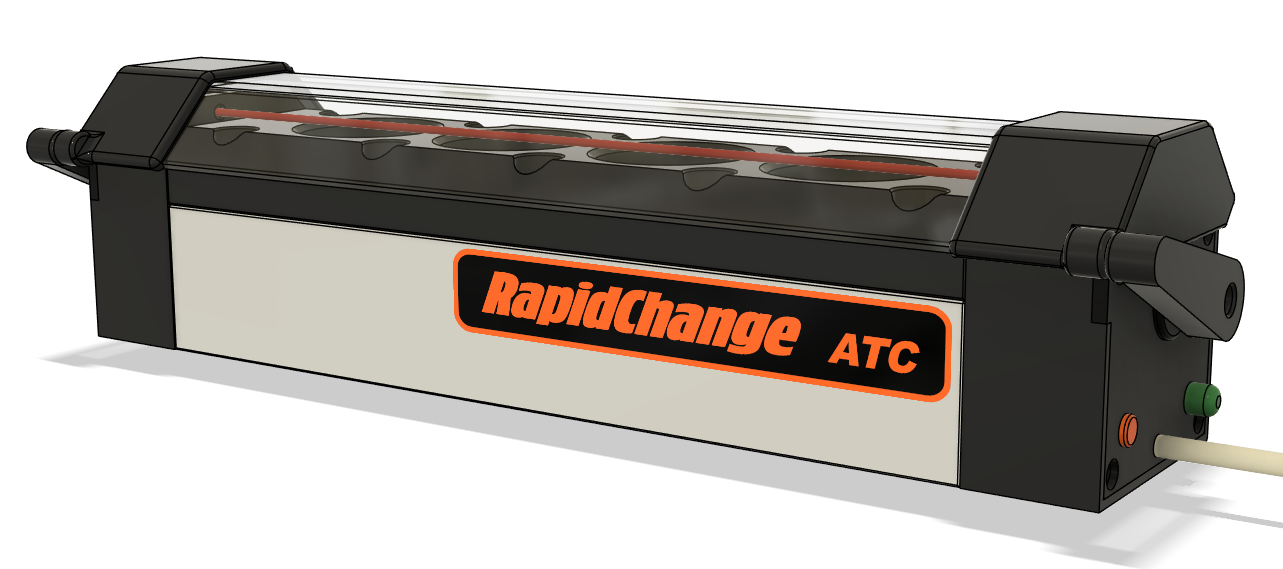

Patent Pending RapidChange ATC Magazines allow for the use of cutting tools with a maximum diameter of 16mm for ER16 collets and is designed for A Type clamping nuts.

The ER16 4 Premium Magazine is equipped with 4 tool tool positions. It allows for safe unattended use by employing our innovative tool recognition sensor. It also includes a clear polycarbonate cover that seals tight to the motor housings providing a good seal against dust and debris.

The RapidChange ATC Magazine is machined from tough HDPE employing our unique patent pending spring loaded socket design. It works with your CNC and common spindle to allow smooth and reliable tool changes out of the box. Aside from a tool setter and the ability to run your spindle in reverse for unloading tools it can be used as a stand alone unit with no inputs or outputs required.

Macros for integrated motion control platforms as well as g code templates for writing your own macros can be downloaded from the website after purchase.

Comprehensive installation Instructions to get you up and running quickly.

Tool Setter Sold Separately. Any external tool setter may be used in the tool change procedure. We are no longer incorporating the adapter for the 3D Probe due to the new low profile cover.

We have developed a tool setter which is optically triggered and very reliable. It actually tested out slightly better than the 3D Probe we had been recommending.

It also is modular so it can be easily added to our current design. Our optical tool setter will be available in our store soon. For the moment if you are interested in this add on option please contact us at info@rapidchangeatc.com

Dust Cover Control has changed for the better. The Premium Linear Magazine now uses servo motors to drive the dust cover through an output on the motion controller. If an output is not available on the controller a limit switch may be used to trigger the dust cover as the spindle moves over the magazine.

All the electronics are tucked nicely into the right end housing on the magazine.

12-24v is required and can be wired to the motion control board main power or a continuous aux power supply.

Red Power 12-24v input (36v upon request such as for a Onefinity Buildbotics controller )

Black Gnd. (If using a separate power supply that of the motion controller the they must share a common ground).

Blue Dust Cover signal wire is connected to an output on the motion controller active Low.

Yellow IR signal wire is connected to an input on the motion controller active High.

Reviews

There are no reviews yet.